Application Guide: Dairy Pumps

Sections:

Tapflo Gulf provides a range of pump solutions for the dairy industry. Having a high-performance pump that’s easy to clean and maintain can be crucial in pumping dairy products such as milk, cheese, butter and yoghurt.

An efficient system, will mean your equipment stays sanitary and your products remain safe for and compliant for human consumption.

Tapflo Gulf have a great range of pumps that can be used for a wide range of dairy applications such as Centrifugal, Lobe and Diaphragm Pumps.

Considerations for a Dairy Pump

Dairy products can easily become stagnant or mouldy if left too long or become trapped within equipment, which means it is imperative that the pump you choose for your application should be sanitary, as the product needs to be safe for consumption. For this, they should have:

- Smooth internal surfaces with gently bends, avoiding sharp angles or parts where the product could be trapped – supporting CIP and SIP.

- Stainless steel construction of the wetted components.

- A superior, polished finish for the casing of the pump for easy cleaning.

Types of Pumps for Dairy

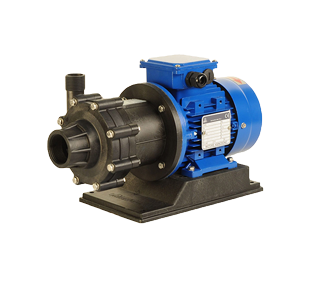

Hygienic Centrifugal Pumps

Our Sanitary Centrifugal Pump portfolio includes the CTH, CTS-H, CPC models, and self-priming options. These pumps are suitable for a range of hygienic applications, including all types of milk (skimmed, raw), butter, cheese and cream. They can withstand high temperatures and offer corrosion resistance. They are ideal for highly aerated fluids with low viscosity like milk.

Sanitary Stainless Steel Centrifugal Pump

PSCP Pumps

Our Pump for Partially Defoamed Starch Milk (PSCP) is constructed from stainless steel and has a simple design which makes it easy to clean, assemble and disassemble. This pump has been designed for transferring the product to hydrocyclones within the starch production process.

Partially Defoamed Starch Milk Pump

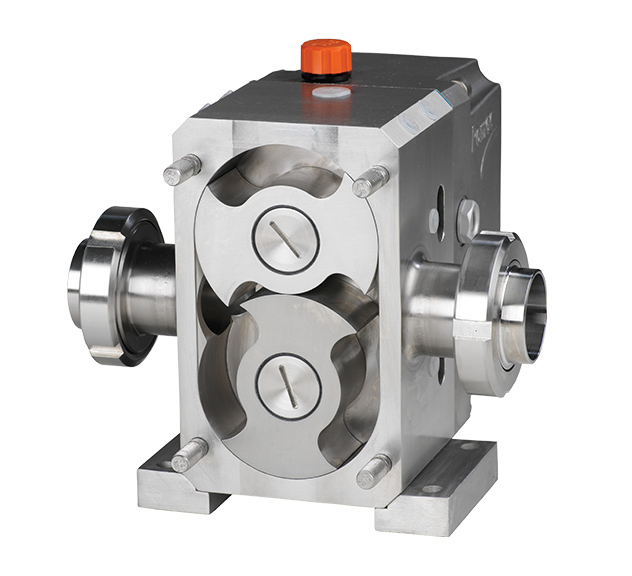

Sanitary Lobe Pump

Our EHEDG Lobe Pump is versatile and designed for the food industry. These pumps are perfect for pumping both low and high-viscosity products gently, and with minimal shear forces. Cross-contamination is eliminated due to the unique gear housing design, ensuring a clean, hygienic application. The cast stainless steel pump meets the highest sanitary standards and supports CIP and SIP for easy cleaning and sterilisation.

Sanitary Lobe Pump

Sanitary Diaphragm Pump

The Sanitary Diaphragm pump is engineered to meet the strict requirements of the food industry. It is both FDA approved and ATEX compliant, ensuring safety. The pump housing features a high-quality, fine finish with no hidden areas where bacteria can grow. The pump can rotate 360° for easy draining supports both CIP and SIP processes. Its clean diaphragm face minimise the risk of leakage and the potential of bacteria growth.

Sanitary Diaphragm Pump

How do I maintain the temperature of my product?

If you need your dairy product to be kept at a specific temperature throughout your application, a heating or cooling jacket can help the pump maintain a consistent temperature. It also helps prevent liquids from solidifying and prevents damage to the pump and mechanical seals. We have these jackets available across our pump ranges.

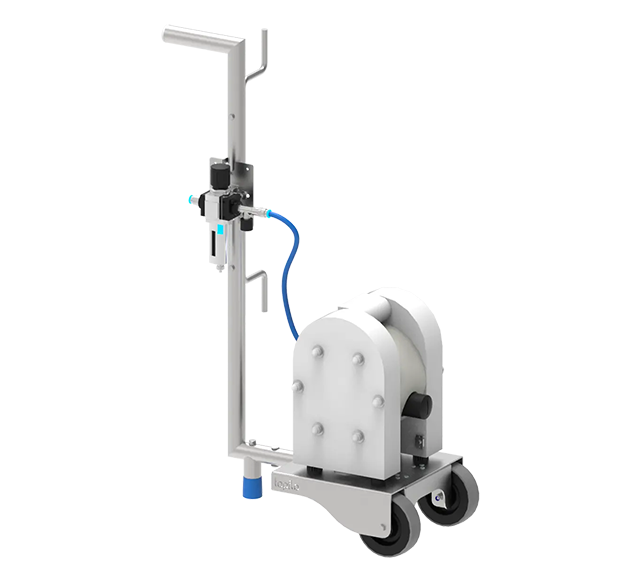

Systems for Dairy applications

If you have a larger scale facility and are searching for a complete solution for your dairy application. Take a look at our High Viscous Drum Unloading System, which is designed to efficiently and precisely unload containers with high-viscosity products such as cream cheese and similar products. Using a Hygienic Progressive Cavity Pump, the system provides smooth transfer of product directly from drums, IBC’s or other containers. An automated system provides an efficient, time-saving solution , and is ATEX-certified meaning it can be used in hazardous environments.

Each system is built for sanitary operation, easy cleaning (CIP/SIP), and regulatory compliance. Tapflo Gulf can customise configurations to suit both small-batch and large-scale operations.

Drum unloading system

Compliance requirements of a Dairy Pump

It’s important that Dairy Pumps have certain compliances and certifications for them to be used in pumping products safe for human consumption.

The requirements for sanitary pumps contain:

- FDA approval – this ensures that the parts in the pump are sanitary and can be used for the food industry. Other ideal things are that they support CIP and SIP, for effective cleaning.

- EHEDG – The European Hygienic Engineering and Design Group is a credential enduring equipment and processes meet stringent hygienic design standards to ensure safety and quality of the product.

- USP-VI – rigorous testing and standards set by the U.S, ensuring that materials don’t cause adverse reactions when coming into contact with humans and demonstrates low toxicity levels.

- 3-A – A set of guidelines to ensure the hygienic design of equipment. This means they must be designed to eliminate hard-to-reach areas where bacteria can accumulate, has smooth internal surfaces to prevent microbial build-up, and compatibility with CIP and SIP systems for effective cleaning.

Looking for your next pump?

Why Trust Tapflo Gulf Pumps & Systems

- Local Expertise: supporting regional compliance with certified solutions for the Food & Beverage industry

- Comprehensive Service: from supply, installation and maintenance to validation and training

- Maintenance & Spares: ensuring long-term reliability and reduced downtime

- Customisation: accessories such as Guardian pump monitoring systems and heating/cooling jackets are available to support your processes

Finding the best pump for your application can be daunting, but our expert sales team can help you with the exact requirements you need.

Contact our team today to find the right solution for your application.