Corrosion-Resistant Pumps for the Chemical Industry

Sections:

When it comes to the chemical industry, we know that each application is different, and there is no “one size fits all” solution. That’s why we offer a wide range of pumps tailored to your specific chemical pumping needs, ensuring safety, efficiency, and reliability.

Our experienced team at Tapflo Gulf can design and manufacture customised systems to suit your requirements, making even the most complex installations that much easier.

Which Pumps are Recommended for Chemical Use?

Our range of pumps for the chemical industry are designed to handle aggressive and corrosive liquids across a variety of temperatures and applications. Safety is critical when using Chemical Pumps, so it’s important to choose the right pump for your operations.

Here are our recommended corrosion-resistant pumps for your chemical pumping needs:

Diaphragm Pumps:

Our Diaphragm Pumps are ideal for chemical handling. They are created from robust materials including solid block HDPE & PTFE, and metal, all of which are highly resistant to aggressive chemicals.

- HDPE (High-Density Polyethylene) is suitable for handling concentrated acids and alkalis at temperatures up to 70°C

- PTFE (Polytetrafluoroethylene) is ideal for aggressive acids at temperatures up to 100°C

- Our Stainless Steel Diaphragm Pumps are a great choice for chemical applications. Both the HDPE/PTFE and metal Diaphragm Pumps can be ATEX-rated, making them safe for hazardous environments. The ATEX-rated PTFE pump is excellent for pumping solvents and other flammable liquids.

Common Applications: Acids, alkalis, alcohols, solvents, latex, emulsions.

Peristaltic Pumps

Peristaltic Pumps are well-suited to chemical applications because the hose is the only part of the pump in contact with the liquid. Our pumps come with chemical-resistant hoses, ensuring safe and efficient operations:

- Low-Pressure Peristaltic Pump: User-friendly and cost-effective due to fewer components, meaning they’re easier to clean and maintain. They can handle pressures up to 4 Bar and temperatures of up to 80ºc

- High-Pressure Peristaltic Pump: are similar to the lower-pressure pumps however, they are capable of handling high pressures of up to 15 Bar.

Common Applications: Acids, PVDF latex, alcohols, soap, non-aromatic solvents, chemical dosing, and petrochemicals.

Flexible Impeller Pumps

Flexible Impeller Pumps are ideal for unloading tanks and drums, making them versatile for various applications. We offer options such as Gearbox Drive and Mechanical Speed Variation with Inverter Drive to suit your installation requirements.

Common Applications: Water-based glues, emulsions, glycerine, wax, rubber latex, photographic processing liquids, paints, industrial discharges, polyelectrolytes.

Screw Pumps

Our Twin-Screw Pump is perfect for the chemical industry. These self-priming pumps are suitable for a variety of applications, including CIP (Clean in Place), SIP (Sterilisation in Place), and dosing chemicals. Twin-Screw Pumps combine the advantages of Lobe, Peristaltic, Centrifugal, and Circumferential Piston Pumps.

Common Applications: Chemical dosing, CIP/SIP, transfer of liquids.

Twin Inlet/Outlet

Centrifugal Pumps

We offer several types of Centrifugal Pumps, depending on your chemical pumping requirements:

- Small Industrial Centrifugal Pumps: Offering high mechanical and corrosion resistance, these pumps are ideal for mild chemicals, and can be ATEX-rated for handling flammable fluids like petrol and diesel

- Magnetically Driven Centrifugal Pumps: These pumps are ideal for safely transferring chemicals. The motor is magnetically attached to the pump, preventing leaks and protecting the pump from damage

- Large Industrial Centrifugal Pumps: Custom-made pumps designed with various impeller and material options, including Cast Iron, Stainless Steel, Duplex Stainless Steel, and Hastelloy. Additionally, these pumps are available in horizontal and vertical configurations

Common Applications: Acids, alkalis, alcohol, solvents, shear-sensitive products (latex, emulsions), chemical waste removal.

Dosing and Metering Pumps

Our range of Dosing and Metering Pumps are built to ensure accurate chemical dosing and fluid transfer, meeting specific accuracy, flow rate, and high-pressure requirements. These pumps are available Hydraulic and Mechanical Diaphragm Pumps, as well as Plunger Pumps. With positive displacement technology, they maintain accurate dosing even in the case of pressure fluctuations.

Common Applications: Chemical dosing, industrial fluids, automotive, water treatment, smart farming and pharmaceuticals.

FAQs

Why trust Tapflo Gulf?

- Local Expertise: supporting regional compliance with certified solutions for the Chemical Industry

- Comprehensive Service: from supply, installation and maintenance to validation and training

- Maintenance & Spares: ensuring long-term reliability and reduced downtime

- Customisation: accessories such as Guardian pump monitoring systems are available as ad-ons

How Can I Make this Pump Safer for Chemical Handling?

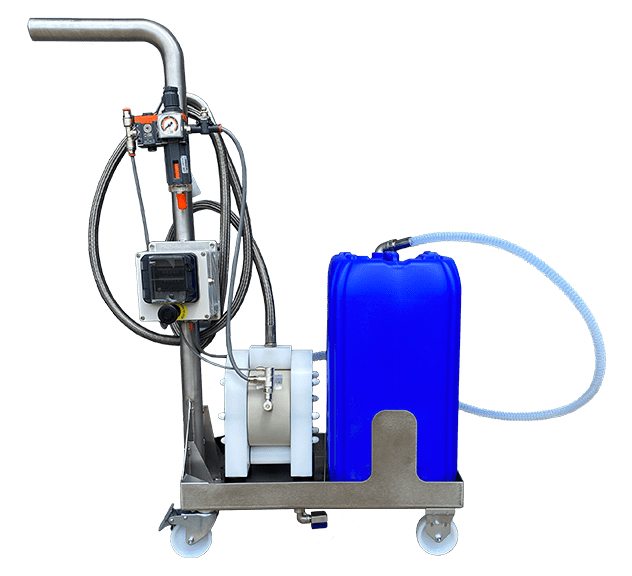

We can install your pump onto a Mobile Decanting Unit (MDU). MDUs make the safe transfer of chemicals easy, with a trolley system that can hold containers of 20L, 25L, or 205L. The MDU also features a pneumatic batching controller.

Can I Detect a Pump Leak Before the Chemical Leaks into The Environment?

Absolutely. Our Diaphragm Pumps can be fitted with a Guardian System to monitor flow pressure. If the pressure drops, indicating a leak, the pump will stop running, and an alarm can alert your team. Our Peristaltic Pumps can also be fitted with detectors to notify you of a hose rupture.

At Tapflo Gulf, we specialise in providing Industrial Pumps and Systems to meet the needs of various industries, especially corrosion-resistant pumps for the chemical industry. If the pumps listed here aren’t quite right for you, feel free to contact our team to discuss your specific requirements or to learn more about our full range of Process Equipment.