Customised Skid System for Large Pharmaceutical Manufacturer

Tapflo is a leading global provider of customised solutions for a wide range of applications and industries, including the Pharmaceutical industry. Our team of experienced engineering experts are committed to delivering high quality solutions and so work closely with clients to ensure that every solution is of the highest quality and reliability. As detailed in the case study below, we provided a skid system designed specifically by our Tapflo Gulf team to meet the unique needs of our customer.

The Challenge

Recently, Tapflo Gulf were approached by a Pharmaceutical Manufacturer in Dubai looking for a compact pump solution that could handle a variety of different solvents, acids and pharmaceutical waste products. Safety and efficiency were a top priority for us, so our team designed a skid system that incorporated a range of our core products, including ATEX, PTFE and Stainless Steel AODD Pumps, Active Pulsation Dampeners and Air Control Units.

The skid system was designed to be robust and easily integrated into the customers modern, state-of-the-art pharmaceutical facility.

The Solution

We worked closely with our customer during the product development process to design an integrated skid solution that combined all their requirements (showcased via 3D modelling).

The skid system comprised the following components:

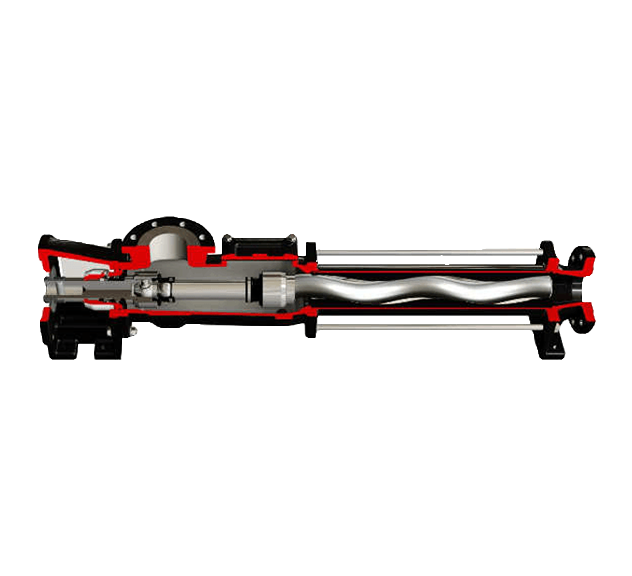

- TXY100-DTX100: Pump with integrated air treatment system and dampener on a frame

- TXY200-DTX200: Pump with integrated air treatment system and dampener on a frame

- TXBY200-DTX200: Pump with integrated air treatment system and dampener on a frame

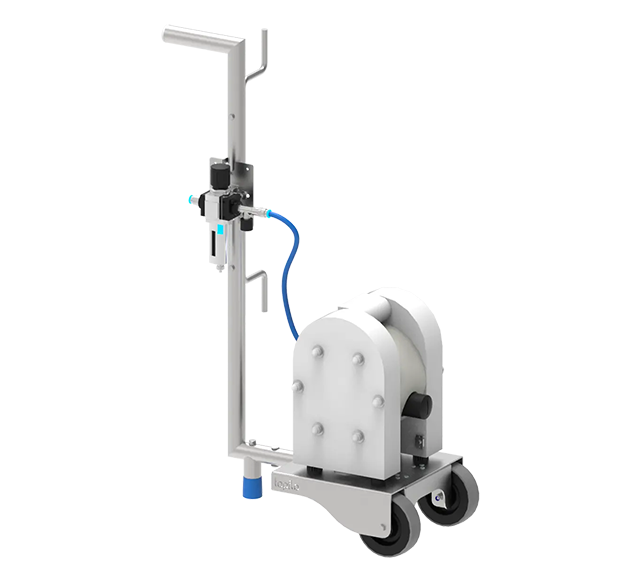

- TXY400-DTX400: Mobile pump with integrated air treatment system and dampener

- TX820-DTX820: Stainless Steel Pump with integrated air treatment system and dampener on a frame

Features & Benefits of the Solution

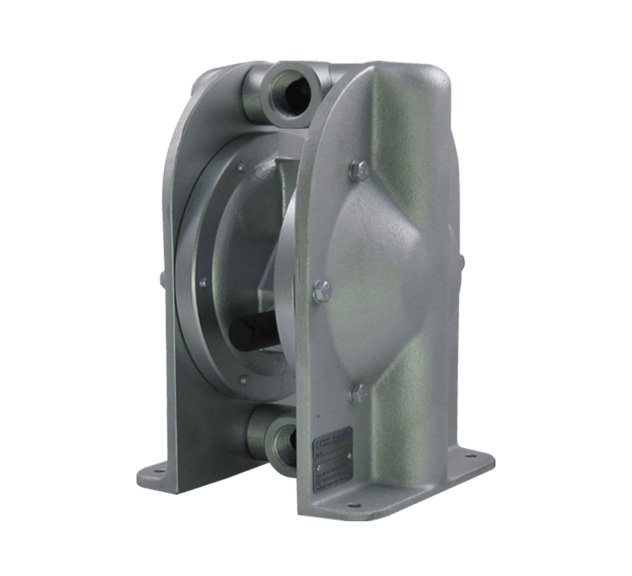

Tapflo Diaphragm Pumps are well-suited for handling aggressive liquids like solvents, acids and waste products due to the following advantages:

- Our Diaphragm Pumps feature a solid block side housing (PTFE AODDs) and cast housing (Stainless Steel AODDs). This ensures chemical resistance, easy maintenance and reliability

- No-nut, clean face Diaphragm Pumps provide added safety by reducing the risk of rupture and leakage of sensitive materials

Conclusion

Tapflo takes great pride in collaborating closely with our customers to deliver solutions that align with their unique business requirements. If you’d like to discuss your customised pump solutions, please contact sales@tapflogulf.com and a team member will be happy to assist you with your requirements.