Your Guide to Centrifugal Pumps

Sections:

At Tapflo Gulf, we offer a comprehensive range of Centrifugal Pumps that have been designed for various Industrial and Hygienic applications, including Wastewater and Chemical handling to Food & Beverage and Pharmaceutical processing. This guide explores what Centrifugal Pumps are, how they operate, our range of Centrifugal Pumps, as well as maintenance best practices.

What is a Centrifugal Pump?

A Centrifugal Pump is a versatile type of process pump designed to move fluids using rotational energy from one or more driven rotors, known as impellers. Fluid enters the quickly rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller’s vane tips. This action increases the fluid’s velocity and pressure, directing it towards the pump outlet.

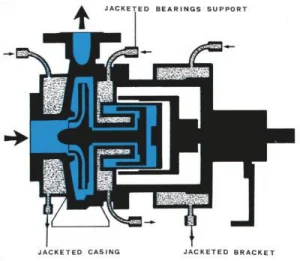

Jacketed Steel Centrifugal Pump

How Does a Centrifugal Pump Work?

Standard Centrifugal Pumps are not self-priming and require their casing to be filled with liquid before starting. When the pump starts, the liquid enters the pump casing at the eye of the impeller. As the impeller rotates, it generates a centrifugal force, drawing the fluid through the pump casing towards the discharge port. This creates a low-pressure point at the eye of the impeller, ensuring continuous suction and fluid draw from the inlet port.

What Material & Drive Options are Available for Centrifugal Pumps?

Our Centrifugal Pumps are available in three different materials:

- Stainless Steel AISI 316L

- PP

- PVDF

With two different drive options:

- Electrically driven

- Magnetically driven

EHEDG Centrifugal Pump

Mechanically Sealed Plastic Centrifugal Pump

Tapflo Gulf’s Range of Centrifugal Pumps

We offer one of the most comprehensive ranges of Centrifugal Pumps, designed to handle everything from industrial chemicals to hygienic food processing. Our range combines durability, efficiency and compliance with the highest industry standards.

Hot Oil Centrifugal Pump

Industrial Centrifugal Pumps

Built for tough applications, our Industrial Centrifugal Pumps deliver reliable performance across sectors such as Water Treatment, Chemicals, Pulp & Paper and Surface Treatment. Available in stainless steel and plastic options, they can be tailored for high-temperature fluids, corrosive chemicals or abrasive slurries.

Sanitary & EHEDG-Certified Centrifugal Pumps

For Food, Beverage and Pharmaceutical applications, we provide Sanitary Centrifugal Pumps with polished finishes and FDA-approved seals to ensure the highest hygiene levels. Our EHEDG-certified pumps go even further, offering exceptional cleanability and compliance with the strictest sanitary standards.

High-Performance & Self-Priming Centrifugal Pumps

When efficiency and versatility are critical, our High-Performance Centrifugal Pumps deliver large flow rates and high pressures, with Self-Priming models capable of lifting fluids from up to 6m. Available in both Industrial and Sanitary versions, these pumps excel in transfer, tank cleaning, dosing and loading operations.

Hot Water & Hot Oil Centrifugal Pumps

Designed for high-temperature processes, our Hot Water and Hot Oil Centrifugal Pumps withstand the thermal and chemical stresses of heating, cooling and heat transfer systems, making them ideal for energy, chemical and process industries.

Specialised Configurations

From space-saving in-line pumps to heavy-duty double suction designs for very high flow rates, we also offer multistage and vertical immersion pumps for demanding environments where high pressure, immersion depth or chemical resistance is required.

What are The Benefits of Using Centrifugal Pumps?

Centrifugal Pumps offer numerous benefits, including:

- Versatility

- Short downtimes

- Low maintenance costs

- Innovative design

- Options for a heating jacket to maintain fluid temperature

- Availability on a trolley-mounted unit

- ATEX-availability

ISO2858 Centrifugal Pump

What Industries and Applications Can a Centrifugal Pump Be Used For?

Centrifugal Pumps are suitable for a wide range of industries and applications, including:

Industrial Applications

- Water treatment

- Mechanical industry

- Paint, print, and varnish industry

- Pulp and paper industry

- Chemical industry

- Surface conditioning

- Demineralising

- Liquid crystal manufacturing

- Photo processing

Hygienic Applications

- Food & Beverage

- Pharmaceutical

How Do I Maintain My Centrifugal Pump?

Regular maintenance is crucial for optimal performance. It’s important to check for wear and tear issues, and to ensure your pump’s flow, pressure, and temperature capabilities are all running at peak levels. Mechanical seals typically require minimal maintenance but replace them promptly if there’s leakage or dry running.

Cavitation

Cavitation occurs when the NPSHa is lower than the NPSHr, causing bubble formation and collapse around the impeller eye, leading to damage. To avoid cavitation you should:

- Operate the pump close to its BEP

- Use regulation valves on the discharge

- Move the pump closer to the fluid source

- Increase pipe size

- Reduce fluid temperature

- Maintain filters

- Ensure no air in the product and suction pipework

FAQs

Can a Centrifugal Pump run dry?

No, running a Centrifugal Pump can dry damage the mechanical seal and motor. Ensure your pump has flooded suction, unless it’s self-priming. Consider dry run protection systems for added safety.

Can a Centrifugal Pump Handle Solids?

Yes, our Centrifugal Pumps can handle solids up to 6mm in diameter.

What is a Centrifugal Pump’s BEP?

The BEP, or best efficiency point, ensures your pump runs efficiently, reducing energy costs and maintenance needs. It is marked on the pump’s performance curve.

How to Specify a Centrifugal Pump?

To correctly spec a Centrifugal Pump for your operation, we’ll need details about the application, flow rates, pressure, product viscosity, and temperature. Contact our sales team for assistance.

Why trust Tapflo Gulf?

- Local Expertise: supporting regional compliance with certified solutions for the Chemical Industry.

- Comprehensive Service: from supply, installation and maintenance to validation and training.

- Maintenance & Spares: ensuring long-term reliability and reduced downtime.

- Customisation: accessories such as Guardian pump monitoring systems are available as ad-ons.

At Tapflo Gulf, we specialise in Industrial and Sanitary Pumps and Systems for key industries. If you need more information, visit our product pages or contact us to discuss your requirements.