Hygienic Lobe Pumps for Chocolate Applications

Sections:

Pumping chocolate might seem simple, but in reality, it’s an art. According to a report conducted by Mordor Intelligence, the UAE Chocolate Market size is expected to grow from USD 525.00 million in 2023 to USD 732.90 million by 2028. And as the demand for chocolate continues to grow, so does the need for reliable and efficient chocolate processing solutions.

The viscosity of this delicious treat can be high, and maintaining its consistency is crucial. At Tapflo Gulf, we understand the challenges of working with chocolate, and that’s where our Hygienic Lobe Pumps come into play. In this article, we’ll look at the world of chocolate processing and how our Lobe Pumps excel in this application.

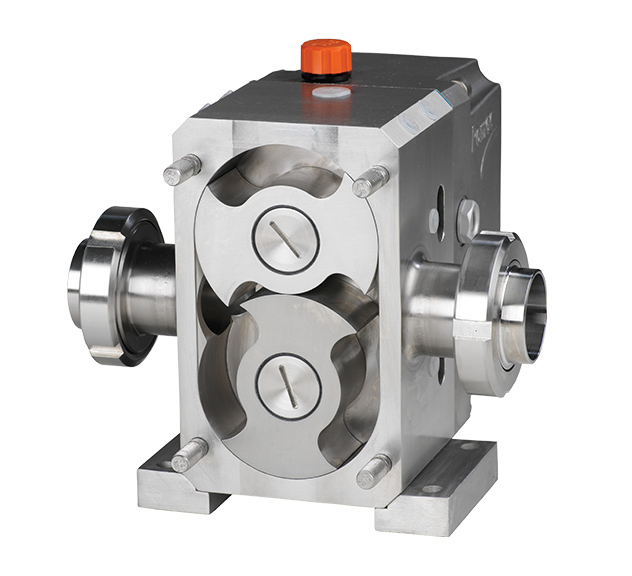

Tapflo's Hygienic Lobe Pump

Our EHEDG-certified Hygienic Lobe Pump is a versatile sanitary solution for the Food, Cosmetic and Pharmaceutical industries. It features CIP and SIP systems for optimal cleaning and sterilisation and meets the highest hygiene standards. Made from Cast Stainless Steel AISI 316L, it offers increased corrosion resistance for Hygienic and Sanitary applications, with Duplex Stainless Steel 1.4462 shafts for added rigidity. Additional features of this pump include:

- Interchangeable sealing options

- Horizontal or vertical mounting options (self-draining when vertical)

- CIP-SIP compatibility

- Max solids passage up to 60mm

- ATEX rating available for use in hazardous environments

Expanded view of the EHEDG-certified Hygienic Lobe Pump

Factors to Consider when Choosing a Chocolate Pump

Now, when it comes to pumping chocolate, there are a number of factors that need to be considered, especially when choosing a pump for your operation. This includes:

Viscosity Matters:

Chocolate is notorious for its high viscosity, making it a challenge to pump. Our Hygienic Lobe Pumps are tailor-made for these situations. These pumps are not only hygienic but also incredibly easy to clean, making them an ideal choice for efficiently handling high-viscosity products like chocolate.

Temperature Control:

Chocolate is tricky when it comes to temperature. Too high, and you risk caramelisation; too low, and you face solidification or crystallisation. To keep your chocolate flowing smoothly, consider fitting a heating jacket to the front cover and/or the pump body. This prevents the chocolate from solidifying inside the pump and causing blockages.

Dealing with Suspended Solids:

In some cases, chocolate contains suspended solids like almonds, hazelnuts or rice. Our pumps come equipped with Bi-Wing lobes, which are designed to minimise damage to these solids, ensuring a smooth pumping process.

Abrasion Protection:

Chocolate is shear-sensitive and it can be abrasive, which makes it prone to caramelisation. High-speed rotations can damage both the product and the pump. To avoid this, we recommend using lower speeds. For chocolate applications, a speed lower than 100 rpm is generally recommended.

Sealing Solutions

Selecting the right sealing system is crucial for different types of chocolate. We offer various sealing options, all compliant with FDA and EC-1935/2004 regulations:

- Single Mechanical Seal Tungsten carbide (TC/TC/FKM): This is our standard choice for chocolate applications, offering durability and resistance to wear and shock

- Double Mechanical Seal (TC/TC/FKM): Suitable for applications with a dry running risk, this seal can be lubricated with food-grade fat or oil. It can handle both low and high pressures

- Double O-Ring Seal with Food-Grade Lubrication (FKM): An economical option for applications with a risk of dry running, this seal can also be lubricated with food-grade fat or oil. Keep in mind that the service life may decrease with higher speed, pressure and abrasiveness

- Food Grade Fat Lubrication: A specially designed lubrication system ensures that the mechanical seals are consistently coated with clean grease rather than chocolate. This reduces wear and tear, as chocolate can be abrasive and lead to rapid wear of the seal faces

Conclusion

In the world of chocolate applications, precision and hygiene are key. Tapflo Gulf’s Hygienic Lobe Pumps are designed to handle the challenges of pumping chocolate efficiently and reliably. With the right pump and sealing solution, you can keep your chocolate flowing smoothly, ensuring a sweet and trouble-free production process.