Guide to Dry Running Your Pump

Sections:

If you have ever worked with pumps, you would have come across the term Dry Running, but what does this mean? This guide will dive into what it is, how it’s caused and how to prevent it.

What is Dry Running?

The Dry Running of a Pump refers to the pump operating without liquid. This causes friction and heat, which in turn damages internal components of the pump.

However, there are ways to avoid your pump running dry, including choosing the right pump and accessories for your application so that your operations run smoothly.

What Causes a Pump to Run Dry?

A pump runs dry when it is operated without liquid at its inlet. This can happen if the supply tank is empty, suction valves are closed, air leaks into the suction line, or the pump isn’t properly primed.

Larger pumps may be damaged more quickly owing to heavier moving parts. Typically, pumps will run dry when they have been left for extended periods of time without proper controls in place. Even short periods of Dry Running can cause damage or overheating in some pump types, like Centrifugal and Gear pumps.

Can Dry Running a Pump Cause any Damage?

One of the most common outcomes when dry running your pump is that the internal components will become extremely hot, causing them to melt or seize up onto the motor shaft. There is potential for this to happen with Centrifugal Pumps, Rotary Vane Pumps and Gear Pumps. This is because these pumps do not have the capability to dry run effectively if there are no additional controls fitted.

Can all Pumps Dry Run?

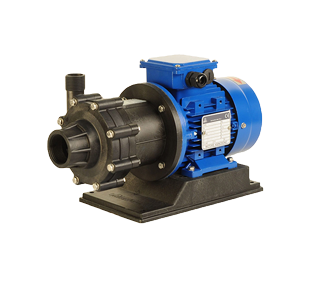

No, not all pumps can Dry Run. Numerous Pump Technologies, like Mag Drive Centrifugal, use the media it transfers to cool down internal parts. Therefore, Dry Running this pump would quickly fail.

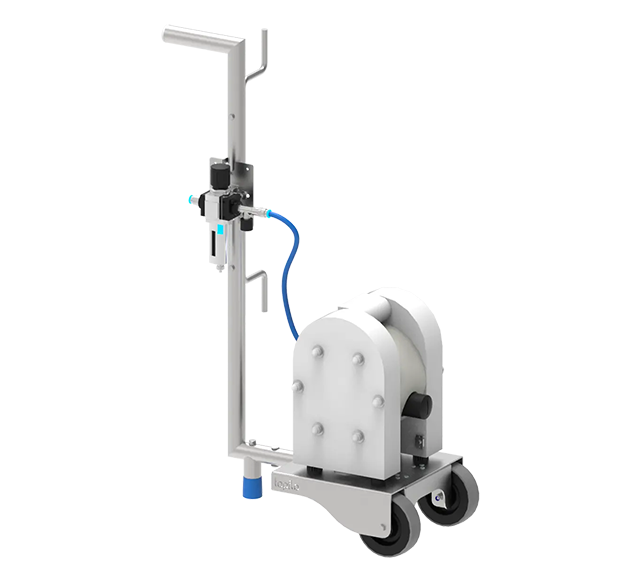

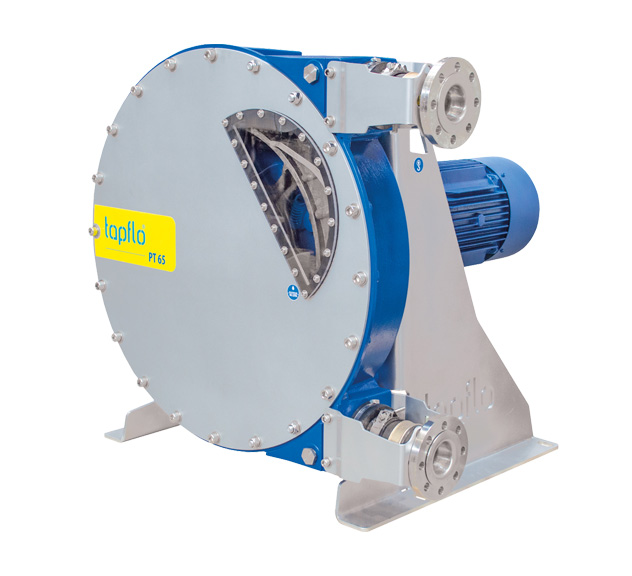

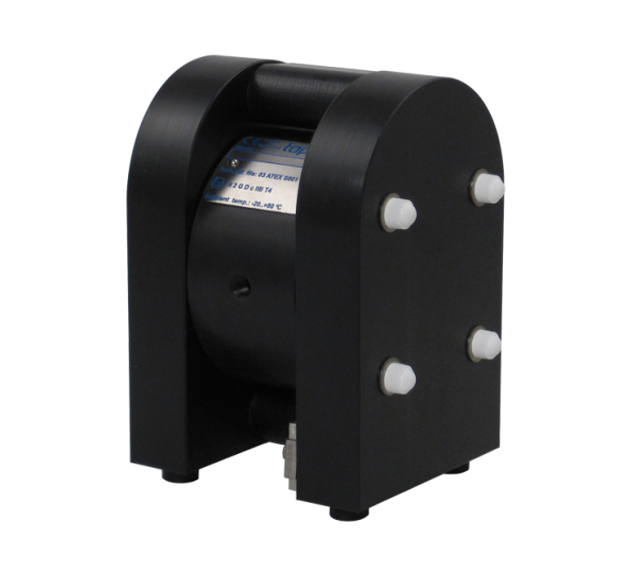

Pumps that are suitable for Dry Running usually utilise a different means of transferring the media. Our dry run pump range includes:

- Diaphragm Pumps: Designed to pull a high vacuum, the self-priming design ensures no damage to the pump.

- Peristaltic Pumps: Built with hoses that are lubricated by the fluids they handle.

- Sliding Vane Pump: Built to be dry priming.

- Sealless Eccentric Disc Pumps: Self-priming with dry priming capabilities.

The means by which these pumps operate allows for Dry Running without any damage to the internal components, ultimately providing the end-user with self-priming capabilities.

How to prevent Dry Running?

Certain pump manufacturers will have to install an accessory device onto the pump to ensure it cannot continue operating when there is no fluid present. For example, a Rotary Lobe Pump would require additional protection to prevent dry running from occurring. There are a variety of options available to suit your application, including the following:

- Frequency inverters: These are used for pumps with three-phase motors to alter the frequency, improving speed operation. Features a start/stop button for control over operation times.

- Flow/pressure switches: Stop the pump when no liquid is detected.

- Batch control system: Ensures the pump only runs for a set amount of time.

With the addition of simple pump accessories, you will be able to reduce the risk of dry running, damaging your pump, and potentially wasting energy and money in your application process.

Looking to Dry Run your application?

At Tapflo Gulf, we supply a range of pumps that can safely run dry, including Diaphragm and Peristaltic Pumps, as well as protection devices to safeguard your pump. Contact our team today to find the right solution for your application.