Application Guide: Pumping Paint

Sections:

Pumping paint and similar fluids requires precision, reliability and the equipment built to handle a wide range of viscosities and chemical properties. In the industrial and manufacturing sectors, selecting the right pump is crucial for efficiency, product quality and safety. At Tapflo Gulf, we offer a range of pumps specifically designed for paints, inks, solvents, adhesives and pigments, ensuring smooth performance, minimal maintenance and maximum uptime for your application.

Typical applications for paint pumps

Below is a list of typical paint pump fluids that are pumped:

- Ink and Pigment transfer: Moving inks from storage tanks to printing of packaging lines.

- Paint Circulation: Recirculating water-based or solvent-based paints in production lines to maintain consistency.

- Varnish and Acrylic Coating: Metered dosing and transfer of coatings in wood, furniture and metal finishing processes.

- Adhesive Handling: Pumping glues and adhesives for packaging, assembly or industrial bonding.

- Solvent and Chemical Transfer: Safe and controlled movement of solvents used in paint formulation or cleaning.

What Paint Pumps can Tapflo Gulf offer?

Flexible Impeller Pump

Flexible Impeller Pumps are well-suited for handling viscous fluids, making them an ideal choice for the paint and printing industries. Their rotating, flexible impellers are designed to bend to fit the pump housing, trapping fluid between the blades to displace fluids. The pumps feature a convenient terminal box that allows for easy operation, including pause and reverse functions. For added versatility, accessories such as trolleys, inverter drives and v-belts are also available.

EP Flexible Impeller Pump

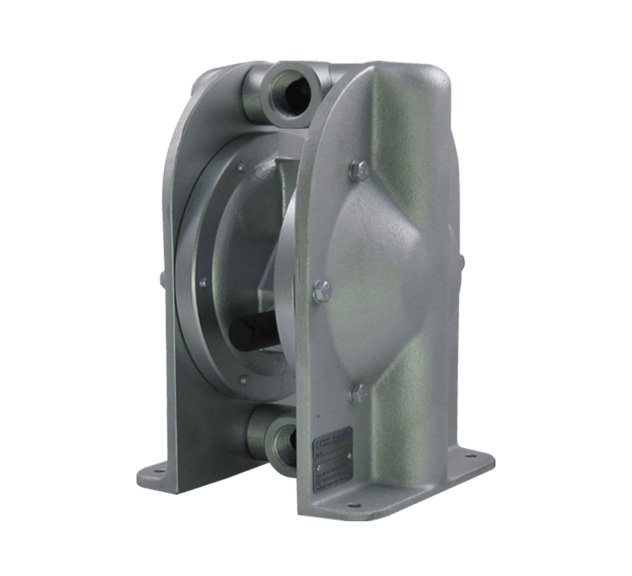

Aluminium Diaphragm Pump

Our Aluminium Diaphragm Pump is designed to handle viscous and chemically aggressive fluids and is available in stainless steel, cast iron and PTFE-coated aluminium. These diaphragm pumps feature approximately 70% fewer parts than other pumps on the market, making maintenance effortless and enhancing flow efficiency through their streamlined design. They are safe, easy to install, and offer high suction lift with reliable self-priming capabilities.

Another suitable diaphragm pump is the solid block plastic HDPE and PTFE pumps, which offer superior wear resistance and chemical resistance compared to standard polypropylene.

Plastic Diaphragm Pump

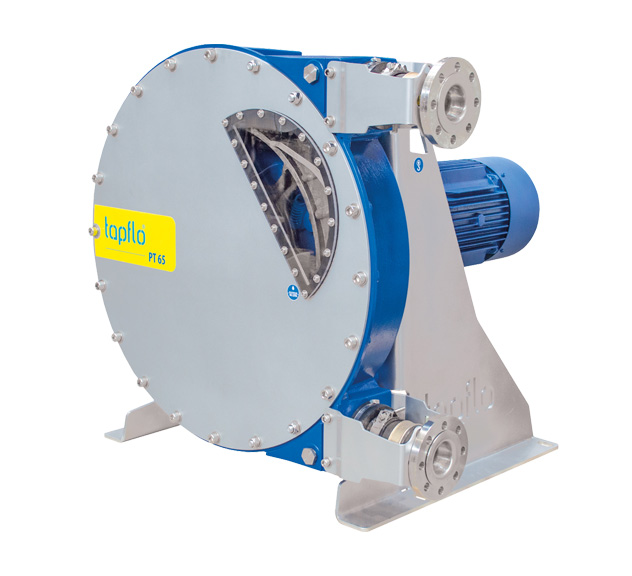

Peristaltic Pump

The High-Pressure Peristaltic Pump is an excellent choice for a Paint Pump due to the following 3 benefits:

- They can run dry without causing unnecessary wear. This means they are a great option when emptying tanks of ink or paint etc.

- Their pulsating flow produces consistency and accuracy when transferring fluids.

- They have excellent dosing capabilities whilst being able to transfer pigments with ease.

With a Peristaltic Pump, there is little to no risk of contamination as the hose is the only part that makes contact with the product. For this reason, we ensure that the hose is manufactured to a high standard for many applications. Our range of hoses are available in brass, aluminium, stainless steel, nylon and polyglass. Additional accessories can also be added, such as Pulsation Dampeners, which reduce vibrations by up to 80%, ensuring a more linear flow.

High Pressure Peristaltic Pump

Powder Diaphragm Pump

Powder Pumps can be used to transfer powder paints and pigments. Tapflo Gulf’s Powder Diaphragm Pump is manufactured from Aluminium and has a PTFE coating that aids the flow of powder through the pump.

This Powder Pump is perfect for companies wanting a portable and more economical pump for their application.

Check out our Powder Pump guide via our Pump Information page.

Powder Pump

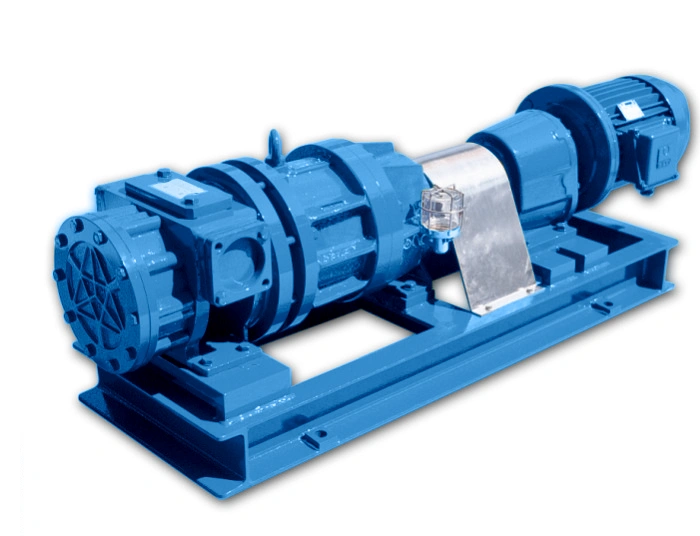

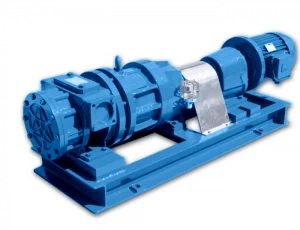

Oscillating piston pump

An Oscillating Piston Pump is another great choice for pumping paints, inks, glues and adhesives. Engineered to produce a constant flow and to handle viscous and shear-sensitive liquids, making it an ideal choice for these types of products.

Heavy-duty pressure parts ensure a robust operation, whilst the spring mechanism allows a wide variety of products, even containing solids to be transferred.

It is leak-proof and adheres to ATEX regulations, contributing to reliability and safety.

Oscillating Piston Pump

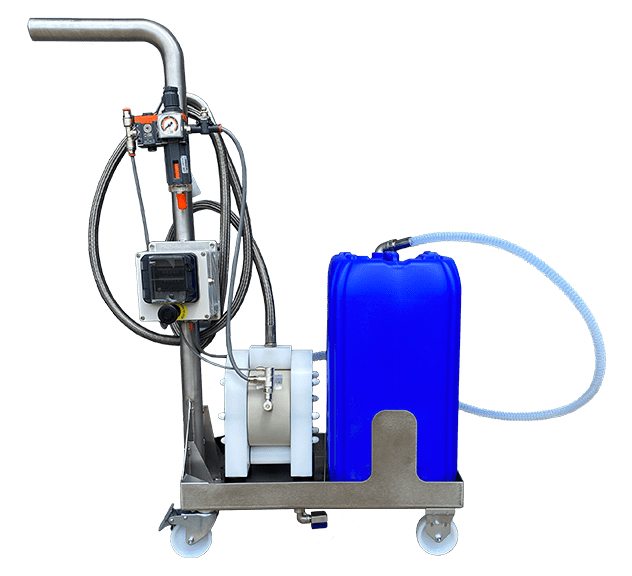

Need a transportable system?

Tapflo Gulf also offer a range of accessories like Mobile Decanting Units. These are purpose-built trollies that hold either 20L, 25L or 205L drums. Drum mixers are great for mixing, blending and agitating within drums. Pneumatic Batch Controllers can also be added to control safety when handling large volumes of product.

Pneumatic Batch Controller

We hope this guide has helped you select your new paint pump. If you require further assistance with your exact application and needs, contact our expert sales team today