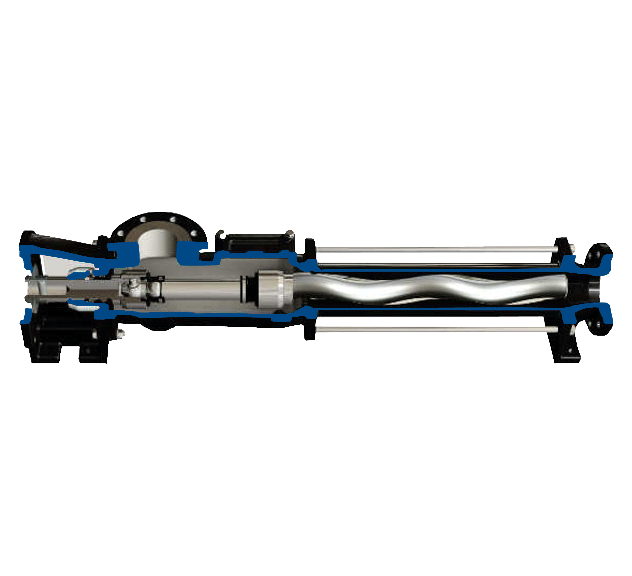

Industrial Progressive Cavity Pump

Max. Flow:

110m³/hr

Max. Head:

480m

Max. Temp:

150°C

Material:

Metal

Our Sanitary Progressive Cavity Pump is an integral part of our Progressive Cavity Pump range encompassing the JX, JXC, JXO, DX, DXC and DXO Models. These pumps are meticulously manufactured to meet 3A and EHEDG compliance standards, ensuring maximum sanitisation within your process. Renowned for their Clean in Place (CIP) and Sterilise in Place (SIP) capabilities, this range delivers exceptional hygiene. This range is also specifically engineered to allow for drainage, further enhancing its suitability for Sanitary applications.

Typical industries for our Sanitary Progressive Cavity Pump:

| Materials | Stainless Steel AISI 316L |

| Max Capacity | 110m³/hr |

| Max Pressure | 480m |

| Self Priming | Yes |

| Max Temperature | 150ºC |

| Viscosity | 0-200+ cSt |

Connection Options:

Tell us what you need to pump and we will supply the solution!

Leave your contact number and our team will be in touch within 30 minutes!

If you have further questions, our Pump Specialists will have the answer. Please don't hesitate to get in touch:

Tel:

+971 4 2352717

Email:

sales@tapflogulf.com

Open hours between:

08:30-17:00 - Mon-Fri