Application Guide: Pumping Jam

Sections:

We understand the challenges in finding the perfect pump solution for your application. However, at Tapflo Gulf, we offer an extensive range of pumps from trusted, high-quality suppliers suited to your business requirements.

If you’re in the food industry and are looking to source a pump that can handle viscous food substances like jam, even when containing small solids, our pumps are designed to handle these products whilst still running smoothly and efficiently.

Our guide and in-house sales experts can help you establish the best options for your needs.

Here is our application guide for pumping jam:

What to Consider When Choosing a Pump for Jam

When selecting pumps to use in the food and beverage industry, it’s important to consider:

- Viscosity: How viscous is your product? Does it require a larger pumps or higher forces?

- Solids Content: Does it contain any solids in the form of whole fruit, pulp or seeds?

- Shear Sensitivity: A key consideration when needing to maintain product structure and integrity.

- Temperature Requirements: Does your process require heating, and does it need to keep its temperature consistent throughout?

- Cleaning & Sterilisation: CIP/SIP compatibility is important for efficiency and sanitation.

- Certifications: Does your pump meet FDA, EHEDG, USP VI, and even ATEX compliance standards?

What pumps are suitable for solids within the product?

If you’re pumping jam that contains small solids, such as fruit pulp or seeds, you will need to consider pumps that are robust enough to deal with these substances effectively.

Within these industries, consumers have high expectations of hygiene from companies to supply them with safe products, using regulatory-compliant equipment. This is where Tapflo Gulf can assist, and these are the pumps we recommend.

Sanitary Lobe Pumps

Sanitary lobe pumps are a type of positive displacement pump specifically engineered for hygienic processing applications. Their unique design features non-contacting lobes, making them well-suited for handling both low and high-viscosity products, even those containing solids of up to 15mm.

With minimal internal contact, an easily cleanable layout, and a well-sealed gear housing, these pumps help prevent cross-contamination. They are fully compatible with SIP (Sterilise-in-Place) and CIP (Clean-in-Place) systems.

They can also be customised with a range of accessories and fittings to suit your specific application. Thanks to their near-pulseless flow, low shear forces, and quiet operation, sanitary lobe pumps are an excellent choice for delicate products like jams.

Sanitary Lobe Pump

Peristaltic Pumps

Peristaltic Pumps (low and high pressure) are ideal for food products containing solids. With easy-to-drain operation and hoses that can be easily removed, cleaned and replaced, supporting both SIP and CIP processes. Minimal parts in this pump make it easy to maintain, resulting in significantly less service costs and downtime.

Other benefits of these pumps are the turbulence-free performance, with a maximum product temperature of 80°c and viscosity of up to 100,000cps.

These pumps come with an extensive list of accessories and options, fitting types, hoses, and dampeners customised to your specific application.

Low Pressure Peristaltic Pump

Twin Screw Pumps

The EDEDG Twin Screw Pump is designed to meet the highest hygiene standards for the food industry. Constructed from EHEDG-compliant cast stainless steel, it supports CIP and SIP.

This pump offers pulsation-free performance, and the twin screws create double the power of a normal single screw pump. It’s capable of dry running and self-priming, and like peristaltic pumps, come with a wide variety of connection types and accessories.

This pump can handle viscous fluids ranging from 0.5 to 1,000,000cps in viscosity, up to 140°c and solids of up to 60mm in diameter.

EHEDG Twin Screw Pump

Centrifugal Pumps

Tapflo Gulf’s EHEDG Centrifugal Pump is created for precision in food processing. This pump ensures optimal sanitary operations and supports SIP and CIP due to stainless steel parts and the ease of cleaning the shaft seal and chamber.

This pump can handle products with solids of up to 10mm and a maximum temperature of 150°c.

EHEDG Centrifugal Pump

Diaphragm Pumps

Our Sanitary Diaphragm Pump is another purpose-built pump for the food and beverage industry.

This pump supports CIP and SIP due to its ability to turn 360° for easy cleaning and drainage. The smooth face and no-nut diaphragm reduces the risk of leakage and bacterial growth, keeping maintenance costs and downtime to a minimum.

Certifications:

- FDA approved

- ATEX-rated

- EHEDG-compliant

- USP VI certified

Sanitary Diaphragm Pump

Systems for pumping jam

For larger-scale facilities or those needing full automation, we offer custom-engineered systems that integrate with our Sanitary Pumps to improve efficiency, accuracy, and hygiene.

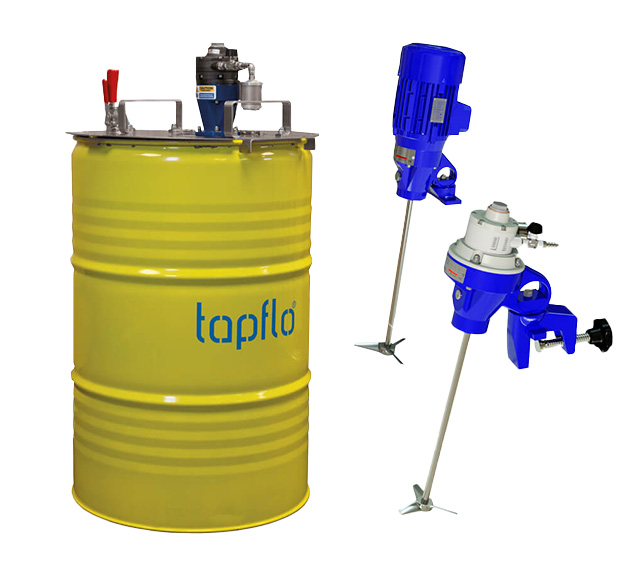

- Drum Mixers and IBC Mixing Stations: Maintain product quality by re-mixing settled liquids directly in IBCs or drums, improving speed and versatility whilst bypassing transitional tanks.

- High Viscosity Unloading System: Purposely designed for highly viscous products that don’t flow as easily. This system efficiently empties barrels whilst delivering optimal performance and hygiene.

Each system is built for sanitary operation, easy cleaning and safety compliance. Tapflo Gulf can customise configurations to suit both small-batch and large-scale operations.

Drum Mixer

FAQs

How do I clean my pump?

To ensure a sterile operation, we supply high-quality stainless steel pumping equipment specifically designed and built for use in the food industry, which can be cleaned by a process called CIP (Clean in Place).

This process which the pump and system are cleaned by flushing a caustic water solution at high temperature (typically 85ºC) through the pump and system to ensure that there are no remnants of the product in the system which may cause bacterial buildup or blockages.

All pumps used in the food & beverage industry should be FDA-approved and designed to have smooth internal surfaces, with no crevices or angles. So that bacteria are unable to build up inside and cause your product to be unsuitable for consumption.

How to avoid your pump clogging

With viscous substances like jam often encapsulating solids, pumps can easily become clogged if the product is left to settle within a pump. This could also occur if the pump is incorrectly sized, where solids can become lodged in the rotating assembly.

However, at Tapflo Gulf, we offer a diverse range of solutions to counteract this problem. One option is the use of a heating/cooling jacket, which can maintain the product temperature and stop it from solidifying within the pump. These work by slowly pushing heated or cooled water through the external jacket of the pump to maintain a certain temperature. The heating fluid doesn’t touch the process fluid, so it will not affect its quality or consistency.

If you’re looking to pump jam or any other similar product, contact our team of sales experts today to see how we can make your process more efficient.